In-service results from Autumn 2022

Impact of Water-Trak on braking

The Water-Trak system fitted to a Northern Class 170 (170473) was enabled on 2nd November 2022. The control chart shows the deceleration rates achieved by the train during step 2 braking with WSP activation before and after the system was enabled. There is a very clear and statistically significant increase in the average deceleration of around 0.9%g. The variation has also reduced with no decelerations below 0.4%g. As a control check, decelerations for the rest of the fleet were analysed and these actually showed a reduction in deceleration over the same time period.

Step 1 braking performance

It was noticed that during the autumn period drivers were braking cautiously and using more step 1 (gentle braking) to slow the trains. Despite this more cautious approach, due to the poor adhesion conditions, wheel slides with WSP activations were still occurring. Deceleration rates for step 1 braking for the fleet and the Water-Trak equipped train are shown in the box plots below. On Class 170 trains, sanding is not enabled during WSP activity in step 1 so the improvement in deceleration of around 0.5%g is due solely to the water addition.

Step 2 braking deceleration before and after Water-Trak switch on (2nd November 2022), all with WSP activation and sanding operational

Step 1 braking deceleration (170473), all with WSP activation except “Good Adhesion” reference (no sanding in step 1), Autumn 2022

Step 2 braking performance Class 170

The box plots show a comparison of step 2 decleration rates between the 170 fleet, the Water-Trak equipped 170473 (off and on) and a good adhesion reference. All the results except the “Good adhesion” reference are during wheel slides with WSP activation and sanding enabled. The improvement in deceleration with water addition is about 0.9%g and equates to a reduced stopping distance of 75m (over a complete train length) when slowing from 50mph.

Step 2 braking performance Class 319

The two Class 319 trains equipped with Water-Trak in2021 (319368 and 319379) were operational again tnroughout autumn 2022. As in 2021, the Water-Trak trains had a significant step up in their braking performance, bringing the average deceleration close to good adhesion performance.

Comparison of step 2 decelerations between the 170 fleet, 170473 (Water-Trak off and on), Autumn 2022

Comparison of step 2 decelerations between the 319 fleet and Water-trak equipped trains (3129368 and 312937), Autumn 2022

Videos of the Water-trak system in action

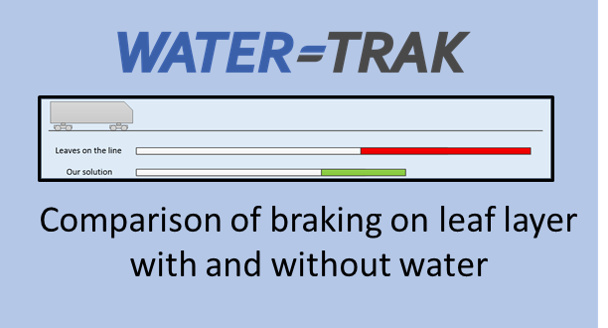

Braking with and with0ut water Addition

A short video of the HydroFlex train braking on a low adhesion leaf layer showing the impact of water addition. Notice the wheels sliding during the braking manoeuvre without water.

Water-Trak System installation on 319368

This video shows a low speed water dispense by 319368 in the Allerton depot, followed by a short tour of the key system components on the vehicle underframe.

High speed Rig testing

Testing water addition at 40mph and 70 mph on the high speed test rig at the University of Huddersfield.

Creating Low Adhesion

Manually creating a low adhesion leaf layer on the rails at the Quinton Rail Technology Centre, (QRTC) Long Marston.

Results from Water-Trak testing (autumn 2021)

Significantly improved braking with Water-Trak

The Water-Trak system was fitted to two Class 319 trains in passenger service throughout Autumn 2021. The trains successfully completed over 37,000 miles of operation and dispensed water 767 times to assist train braking or traction. The braking performance was analysed by calculating deceleration rates for the Water-Trak equipped trains and comparing this to other Class 319 trains operating on the same lines of route. The graphs below show the improvement in both step 2 and full service braking. It is important to note that as well as the average deceleration increasing with water addition, there is also an important reduction in the variation, particularly removing some of the very low decelerations.

Comparison of deceleration rates in step 2 braking (Water-Trak equipped trains v other Class 319s)

Comparison of deceleration rates in full service braking (Water-Trak equipped trains v other Class 319s)

Significantly improved traction

In addition to dispensing water during braking wheel slides (WSP), Water-Trak was also connected to the manual sanding button in the driver’s cab, triggering a water dispense when the driver requested traction sand. The traction performance was analysed by looking at the train acceleration when water was dispensed and comparing this to other Class 319 trains without the Water-Trak system. The graphs below show a statistically significant improvement in acceleration when water was dispensed. The improvement is particularly large at the lower train speeds.

Comparison of acceleration rates (Water-Trak equipped trains v other Class 319s)

Acceleration rates at different train speeds

Results from earlier testing

Deceleration Rates (HydroFlex testing)

A comparison of deceleration rates with sanding only and sanding + water addition from 18mph. The graph shows a statistically significant difference in the mean of 1.8%g. This equates to stopping distances of 111m with sand only and 69m with sand + water - a reduction of more than 40m!

(Testing conducted at Long Marston using the HydroFLEX Class 319)

Braking distance Reduction

A comparison of braking distance from 25mph, comparing with and without water addition on a leaf layer. The good braking performance after water addition (Post Water) demonstrates the potential cleaning effect of water addition.

(Testing conducted at Long Marston using Class 117 DMU)